Magnesite is a carbonate mineral that mainly contains magnesium minerals, as well as other elements such as iron and manganese. In nature, it generally exists in the form of gray, white, brown crystals, and sometimes in block or irregular shapes. The main component of magnesite is magnesium carbonate, with a hardness of 3.5-4 and a density of 3.0-3.2 g/cm³. The hardness and density are relatively low and easier to mine.

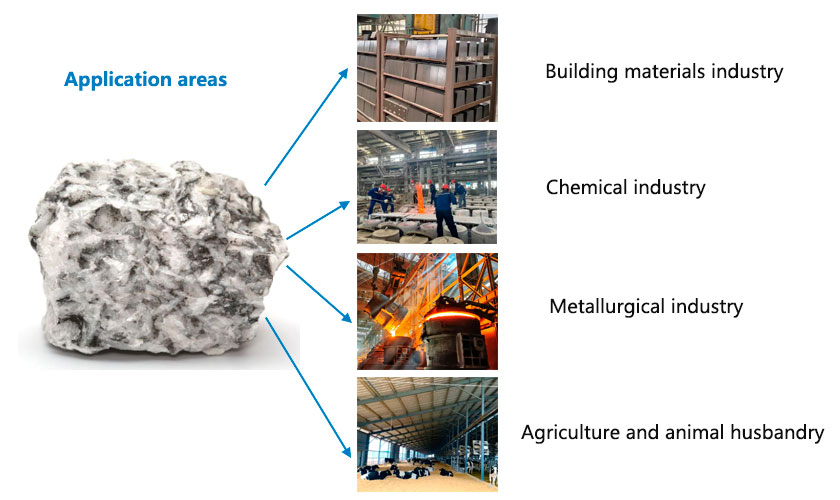

Magnesite is an important mineral resource with relatively stable chemical properties. It exists stably under high temperature and high pressure conditions and is widely used in the construction field.

It can be used as a lightweight, heat-insulating, and fire-proof building material, such as magnesite bricks and magnesite boards. In the chemical industry, it can be used to produce products such as magnesium oxide and magnesium salts.

Magnesium is an important lightweight metal with high strength, high thermal conductivity, high electromagnetic shielding, and other characteristics. It has high economic value and is widely used in aerospace, electronics, and automotive fields.

Characteristics of magnesite

1. High magnesium content: Magnesite contains more than 40% magnesium and is widely used in the manufacture of lightweight materials and magnesium alloys.

2. High stability: Magnesite is chemically stable, not easily dissolved by acid or alkali, and has good refractory properties. It is particularly suitable for manufacturing thermal insulation materials, refractory materials, etc.

3. Beautiful crystals: Magnesite has beautiful crystal shapes and is a common mineral collection.

Mining and beneficiation process of magnesite

There are two ways to mine magnesite, open-pit mining and underground mining.

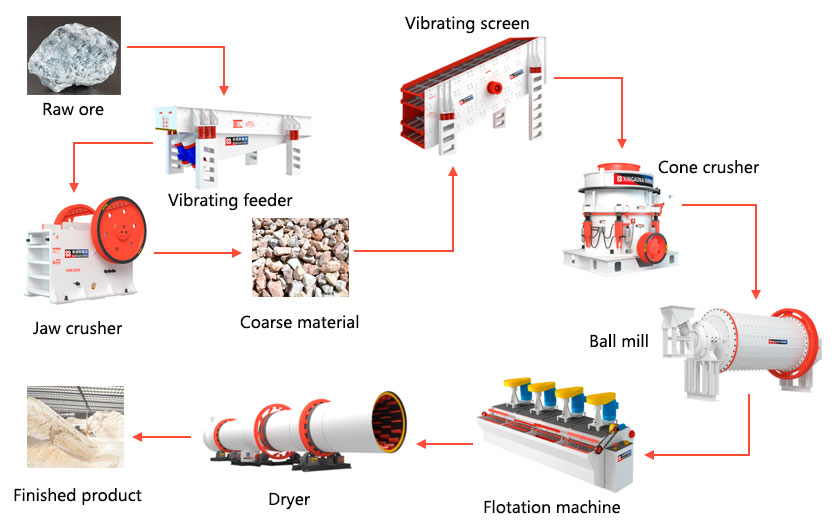

The purpose of magnesite beneficiation is to classify the ore and separate the useful minerals from the waste rock through grinding, flotation, dehydration and other processes. The following is the main process of magnesite beneficiation.

1. Crushing and screening: The raw ore is crushed to 10-0mm by jaw crusher, Cone Crusher and vibrating screen in a two-stage closed-circuit process, and the sieving machine is used to control the particle size of the mineral.

2. Grinding and classification: After grinding and screening, the ore is ground to about 200 mesh and then flotation is performed.

3. Flotation: The flotation process consists of reverse flotation and forward flotation. The former selects all tailings, and the latter obtains magnesium concentrate and middlings.

4. Dehydration: The magnesite pulp separated by flotation is dehydrated by a filter press or centrifuge to separate the water. The remaining solid mineral is called concentrate.

In short, magnesite is an important mineral resource with many uses and forms. Through the above article, we understand the properties of magnesite, as well as the mining and beneficiation process of magnesite. With the development of science and technology, the application field of magnesite continues to expand, and it will play a more important role in the future social development.

The properties and process flow of magnesite_Industral news_Xingaonai Group

Comments on “The properties and process flow of magnesite”